Find out how you can digitalize your production

with solutions from MPDV!

Distributed Control System / DCS – Smart Factory Glossary

A Distributed Control System (DCS) is an IT system that monitors and controls processes and production facilities. For this purpose, the control system continuously collects machine data, analyzes it, and makes decisions based on evaluations to control machines and processes. The system helps to ensure that processes are efficient, safe, and reliable, while at the same time quality is increased and operating costs reduced.

The DCS comprises the following components:

- Process-related components are connected to field devices such as sensors or actuators, which in turn are directly connected to the production processes.

- User-oriented components include operating and monitoring stations, for example. They are usually integrated in a shop floor scheduling, connected to the process-related components, and are used to visualize the system.

- Engineering components are used to configure the DCS.

Integration of the DCS into the production IT system

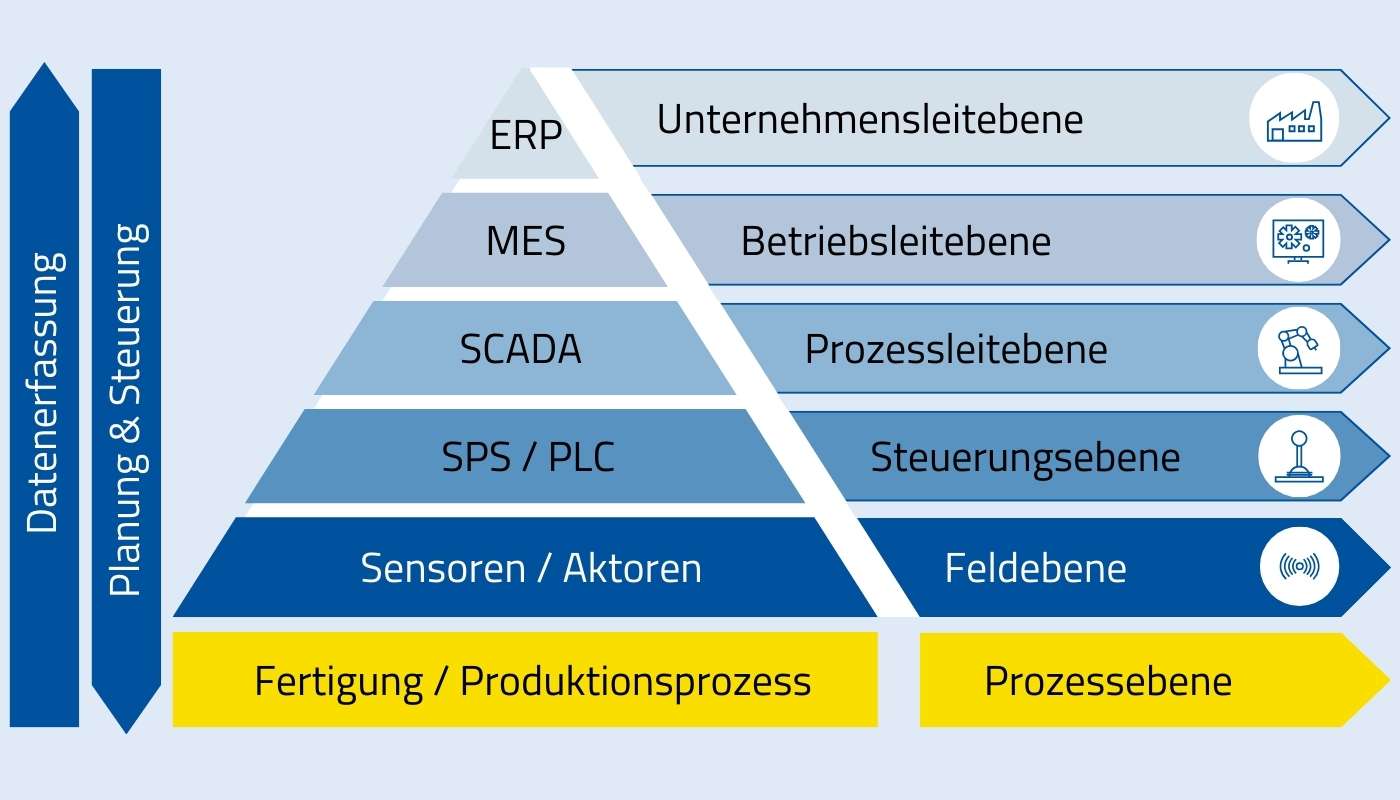

Based on the classic computer-integrated manufacturing of the 1980s with its functional levels, the DCS is assigned to the process control level, which is separated at the lower level from the control level and at the upper level from the plant management level with the Manufacturing Execution System on top. The process control level in the process industry includes functions that are provided by a DCS.

However, as the functional scope of the individual systems increases, the distinctions between the different levels and the associated systems like a DCS, logistics systems, ERP, and MES are becoming increasingly blurred. The pyramid will be replaced over time by other concepts that are based on the principle of decentralization and require a high level of integration capability. The Smart Factory Hive developed by MPDV is one of these new concepts. The multi-layered honeycomb structure shows how systems can communicate with each other independently of their level. To reduce the complexity that arises from such a visualization, MPDV relies on a central platform. All systems and devices are connected to it via standardized interfaces – including the process control system.

MPDV has been developing a platform for several year and offers with the Manufacturing Execution System (MES) HYDRA X and the Advanced Planning and Scheduling System (APS) FEDRA software solutions that meet a wide range of IT requirements in the manufacturing industry. As these systems are based on the Manufacturing Integration Platform (MIP) with a vendor-neutral ecosystem, MPDV software solutions enable a flexible interaction between a variety of applications.

Source

- Distributed control system: Wikipedia, 27.09.2023 [online] https://en.wikipedia.org/wiki/Distributed_control_system (requested on 28.12.2023).

Would you like more information? We are happy to help.

Just fill in the form below. We will take care of your inquiry promptly.