Find out how you can digitalize your production

with solutions from MPDV!

Machine Data Collection / MDC – Smart Factory Glossary

Machine data collection, or MDC for short, refers to the recording of machine statuses in production and the transfer of this data to suitable software. MDC systems evaluate and correlate data with other production data to enable operators or production controlling to draw conclusions.

With the help of MDC software, manufacturing companies monitor their machines in real time and can react to malfunctions instantly. The collected data can also be analyzed at a later stage in order to optimize production in the long term. The aim of machine data collection is to retain machine reliability and readiness to improve machine utilization and thus increase productivity.

Collect, evaluate, and visualize data with MDC software

MDC software manages the entire process: from the collection of machine data and its evaluation to the visualization in meaningful charts and data tables. In order to create the necessary transparency, the collected data must be up-to-date and dependable. Once the data is evaluated, the weak points in production reveal themselves. The information can also be applied to calculate key manufacturing metrics such as OEE and capacity utilization, required by production management and controlling.

What does MDC have to do with PDC and MES?

Machine Data Collection (MDC) is part of the Production Data Collection (PDC). Machine data falls into the subgroup of technical production data and is further divided into process and product data. Technical and organizational production data (order and personnel data) are forwarded to a Manufacturing Execution System (MES) and the MES processes and visualizes the data. Even though manufacturing IT encompasses much more, PDC and MDC still contain basic functions. Without these functions many tasks would be almost impossible to manage. Only if systems are perfectly networked, as in MES HYDRA X from MPDV, can companies fully exploit their potential in manufacturing and improve their production processes in the long term.

What kind of machine data do are available in production?

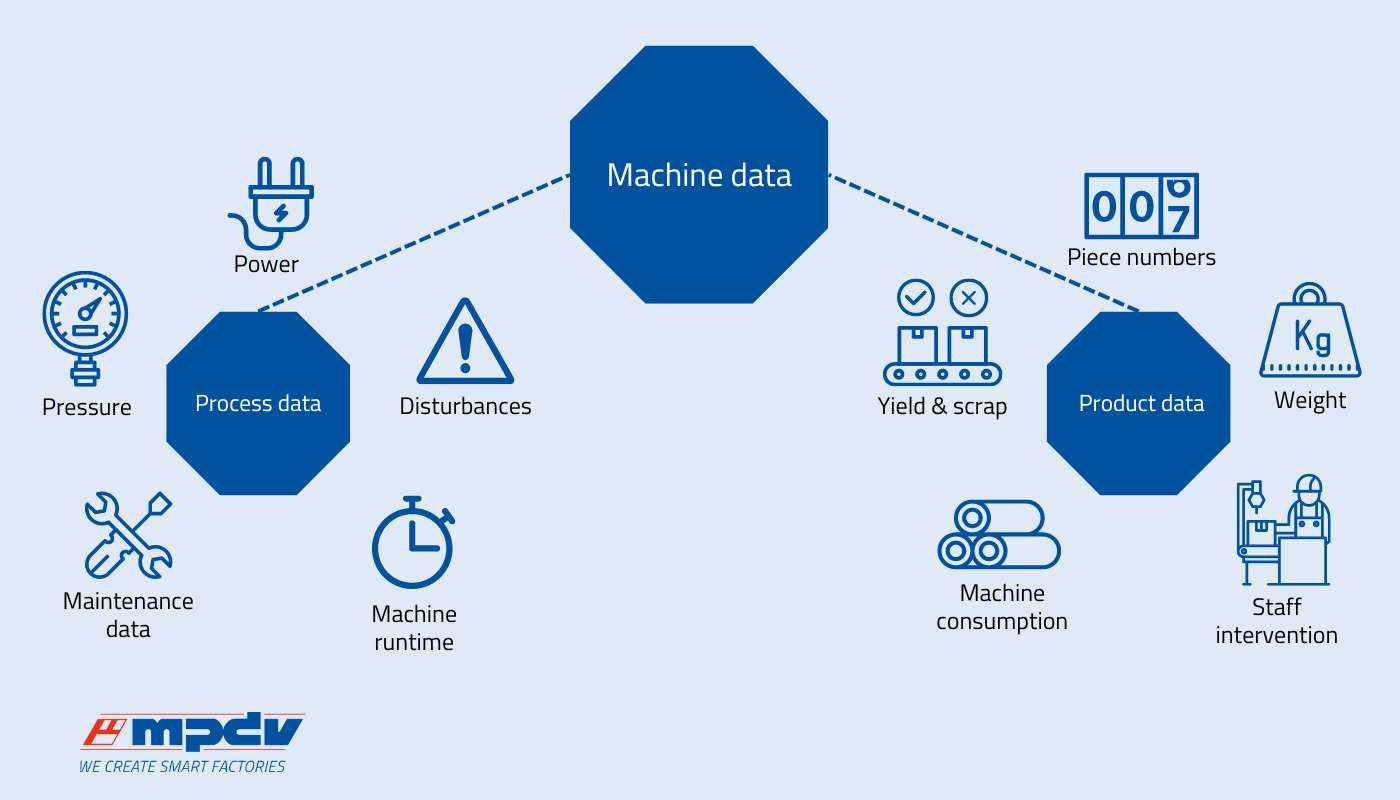

Machine data is subdivided into process data and product data, which are, among others, machine status, energy consumption, utilization, runtime, availability, and reliability.

- Process data includes all information needed to run machines. The data is generated during operation. These are, for example, temperature, pressure, humidity, process parameters, and quality factors.

- Product data is related to the generated product. Typical product data includes the number of parts manufactured, product weight, or serial numbers.

Benefits of a state-of-the-art machine data collection

Companies use machine data collection to increase transparency in their production and keep track of their machines and systems at all times. Piece counts or linear meters allow conclusions to be drawn about output and utilization. The user can record machine statuses like setup, startup, organizational downtimes (e.g., no material, tool missing, waiting for maintenance), and technical faults (e.g., issues with tools, electrical or mechanical faults). Such interfering signals can be used to assess reliability and runtime of machines.

Find below further advantages of MDC:

- No more unreliable and time-consuming manual recordings.

- Full transparency on current machine conditions and incorporation of data in the Continuous Improvement Process (CIP).

- Maintenance processes are optimized based on reliable actual data.

- Machine utilization is maximized by reducing downtime and malfunctions.

- Machine utilization times are increased, and precise knowledge of machine data supports production controlling when making investment decisions.

Functions of machine data collection in the MES

The MDC collects data from machines and equipment of all kinds and stores it in the Manufacturing Execution System (MES). Machine data is stored in a central point in the MES HYDRA X in order for other applications to access it and thus providing detailed evaluations. To do so, the machine data collection automatically transfers machine data from the machine control system via standardized or proprietary interfaces and protocols (e.g., OPC-UA, UMCM, XML, FTP, MTConnect, MQTT, Euromap 63, Euromap 77). It is also possible to document machine data manually via shop floor terminals or simple input devices.

An MDC system evaluates the real-time data recorded in the shop floor, such as the machine status or the number of pieces produced, in relation to the machine. Important KPIs such as Overall Equipment Effectiveness (OEE) are calculated from this data and displayed in meaningful charts. Each employee knows at all times whether production is running or if action needs to be taken. Data can be visualized on large screens in production halls with a shop floor monitor application informing on all aspects of the machine.

Providing and visualizing data is the first step to significantly increase machine availability as well as the utilization of machines and equipment. In combination with a data-based, predictive maintenance strategy, productivity can be significantly stepped up. Furthermore, machine data enables responsive detailed planning or forms a reliable basis for calculating incentive wages and premium pay. In conjunction with other manufacturing apps, things like energy consumption can also be accurately analyzed and ultimately optimized.

Which options for machine data collection does MES HYDRA X from MPDV offer?

In the manufacturing execution system HYDRA X, machine data collection is performed by the mApp Machine Monitoring. The application records machine status and produced quantities via a digital interface between MES and machine control. The user can also enter data manually. Before data is assigned to the corresponding workplace, a plausibility check is performed. If this is not successful, data can be corrected subsequently. All workplaces or machines are clearly displayed in tables, including their current status.

Die mApp Machine Monitoring is included in the Category Resource Management. The mApp can be combined with other applications, also from other categories or third-party providers. This is possible because HYDRA X is a platform-based Manufacturing Execution System that can be individually configured and tailored to custom requirements.

Would you like more information? We are happy to help.

Just fill in the form below. We will take care of your inquiry promptly.