Find out how you can digitalize your production

with solutions from MPDV!

Shop Floor Data Collection / PDC – Smart Factory Glossary

Production data collection or PDC for short refers to the collection of data that is generated when industrial companies process production orders. The data includes information related to orders and personnel and is used for further evaluations.

Order data includes production and order times, status postings and simple quality data. This allows, for example, to differentiate between yield and scrap and also document scrap accurately. In addition, material consumption and data on production resources and tools are recorded and assigned to individual orders. Working hours and break times recorded with the Time & Attendance application, however, are regarded as shop floor data for personnel. The following section further breaks down shop floor data.

What kind of shop floor data is available in production?

Essential organizational shop floor data is:

- Order data such as the start and end of operations, the completion of production orders, production quantities, and quality factors

- Personnel data like information on attendance, piecework, and payment data

Essential technical shop floor data are:

- Tool data like maintenance times of defects

- Material data including warehouse data like goods receipt, goods issue, reservations, and stocks

- Machine data such as assignment times, machine running times, interruptions, malfunctions, energy consumption, and temperature values

- Process data such as temperature, pressure, speed, moisture, process parameters, and quality factors

- Product data such as the number of parts manufactured, their weight, and serial numbers

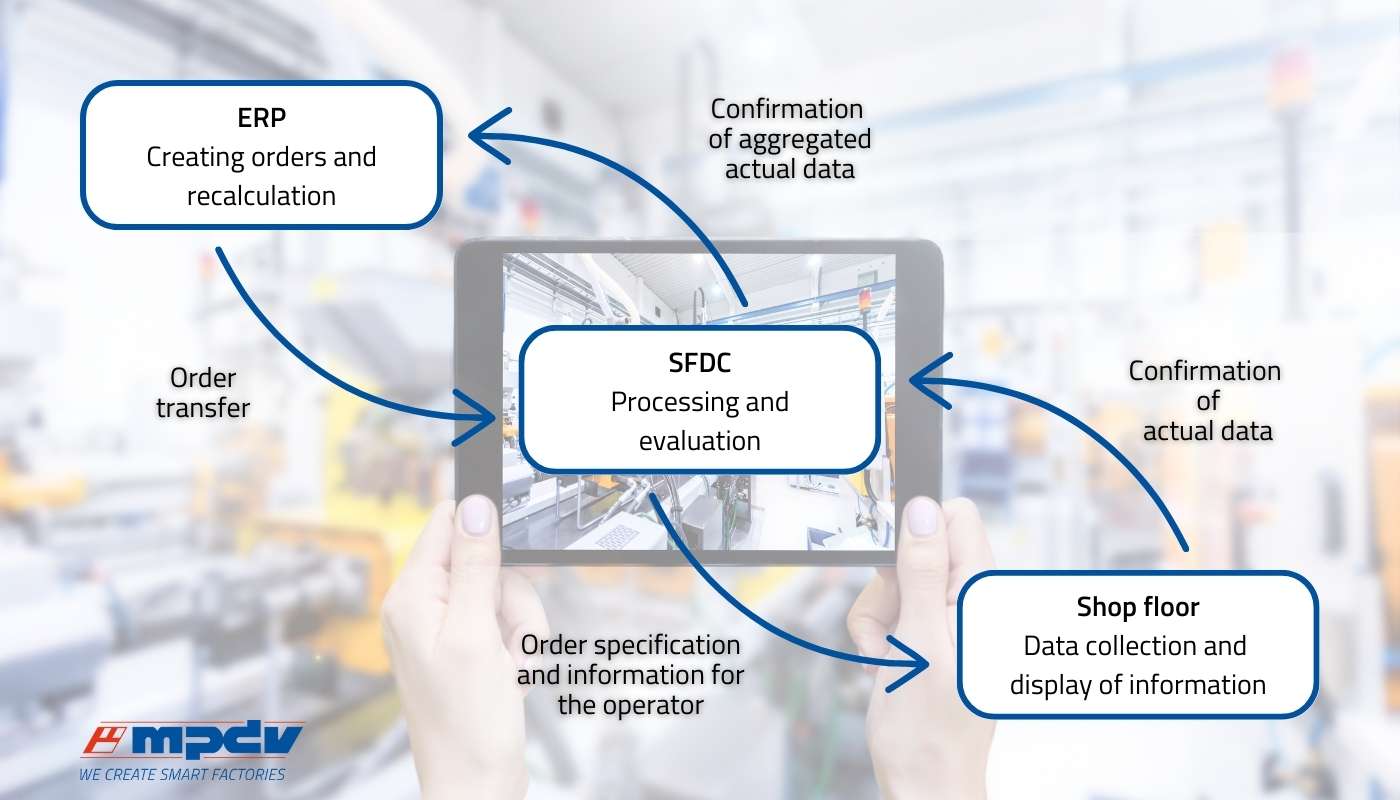

How does a PDC system work?

A PDC system helps departments close to production to record and evaluate order and article data according to their own specifications. Company-specific statistics enable to identify problems in the manufacturing process at an early stage. Employees can then deduce improvements and take the findings on board for future actions. Shop floor data collection thus provides important feedback for production planning and control, which can be used to achieve a more effective organization of production processes.

Either the machine operator manually records the quantities and status information on the shop floor terminal, or the data is read out directly from the machine or its control system via interface. Afterwards, the software accumulates and prepares the data collected during the shifts and over the course of days and weeks. Production managers can make detailed target/actual comparisons instantly. As in any other area, the same applies to shop floor data collection: the more data collected, the more meaningful the picture of production.

Based on the collected data, four central questions in manufacturing can be answered:

- Where is manufacturing done?

- What is manufactured?

- Who is working on what order?

- What costs are incurred in the production of articles?

What does PDC have to do with MDC and MES?

Organizational shop floor data and technical shop floor data are transferred to a Manufacturing Execution System (MES). The MES then further processes and visualizes the data. Machine data can be counted as technical shop floor data, and machine data collection (MDC) can be seen as part of shop floor data collection (PDC). In order to achieve long-term improvements in production processes and to exploit their full potential, all systems should be networked with each other.

What are the benefits of the shop floor data collection?

Companies gain transparency in manufacturing by continuously collecting their shop floor data. Only with accurate knowledge of data can these be correlated in order to draw conclusions about production and optimize processes as a next step. This makes PDC one of the key success factors for remaining competitive in the future. Depending on the provider, order-related information management also falls within the scope of a PDC. The aim is to support the production process with digital information and to supply actual data from the shop floor in real time. This includes, for example, reliable information on the progress of orders.

A dedicated PDC software promises the following benefits:

- The company has full transparency with regard to production processes.

- Delivery dates can be monitored closely, on-time delivery is improved, and express shipments can be avoided.

- Lead times and wait times are reduced.

- Data quality is generally boosted that also benefits the ERP.

- Piecework or premium wages can be easily calculated by using detailed activity records.

- Thanks to virtually paperless production, fewer errors occur, and costs are significantly lowered.

Simultaneously, diverse evaluations and KPIs from the shop floor data collection form the basis for the entire production control. Actual PDC data also permits improved cost accounting and post-calculation in the ERP. Production controlling also benefits from the increased transparency.

What kind of information can be generated with a PDC?

From production control to controlling: Shop floor data collection provides information for many areas.

- In production control, a PDC system supports with easy-to-use sequence planning functions and returns overviews for neighboring areas like: Order backlog, Sequencing list, Material requirements list, Setup change list.

- Order monitoring helps supervisors and shift managers to keep track of current orders and operations. The PDC displays the current status including order progress in real time, calculates lead times, wait times and transport times, facilitates order-related deadline controlling and facilitates the comparison of target specifications with actual values.

- Order controlling is used to evaluate past shifts, production days or weeks in order to derive optimizations in terms of a continuous improvement process (CIP). In addition to shift logs, order, article and scrap statistics form the data basis for this.

- Data collection is the paperless, precise recording of production times and quantities including plausibility checks.

- Depending on the provider, digital interaction with the operator can also be part of the PDC. The Operator guidance displays order-relevant data such as drawings, inspection instructions, or parts lists to the users on their terminal.

To achieve the greatest possible benefit from data, the exchange of data with common ERP systems should be a matter of course. An advanced shop floor data collection system also has flexible administration and maintenance functions to manage work plans and other master data or to make subsequent corrections.

Options for the collection of shop floor data in the Manufacturing Execution System HYDRA X from MPDV

Since HYDRA X is a platform-based MES that gives companies maximum flexibility, the functions to collect shop floor data are mapped via Manufacturing Apps (mApps). These mApps can be combined with each other as required thanks to the MIP integration platform. Depending on the area of use, applications of the shop floor data collection are assigned to different HYDRA X categories. For example, the category Order Management provides PDC applications that record order times, quantity and status information or even person-related times. Or the category Resource Management contains mApps evaluating machine data or process data. All data collected can be correlated with information from other areas such as Quality Management, which is a significant advantage compared to other systems.

Would you like more information? We are happy to help.

Just fill in the form below. We will take care of your inquiry promptly.