CNC Program Optimizer

JITbase

JITbase Optimizer helps methods engineering analyze production historical data in order to align program timing with production reality.

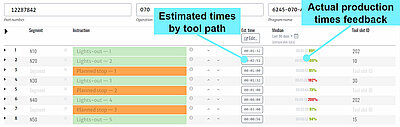

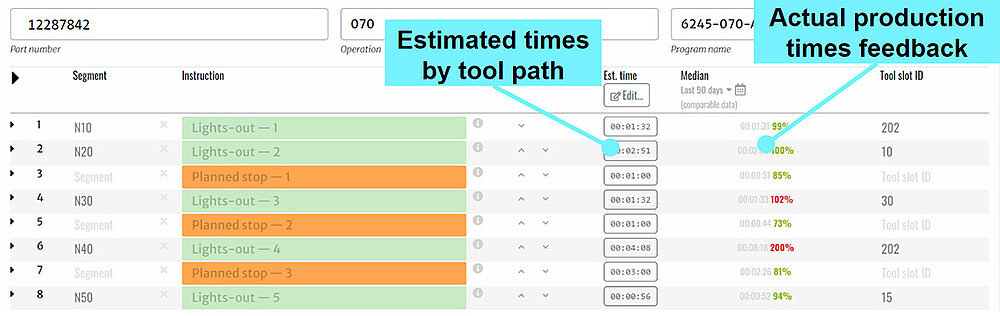

Detect planned stops (M00) that take longer than expected

➔ Update time estimation for better costing and production planning

➔ Or improve current process to help operators respect standard time

➔ Share best practices from best operators

Remove unnecessary Planned stops (M00)

➔ Reduce human interventions by detecting planned stops not performed in production

➔ Extend Lights-Out period with no human intervention

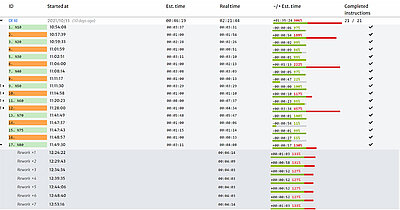

Detect and reduce unplanned Spring cuts/Reworks

➔ Identify tool paths that lead to unplanned spring cuts/reworks

➔ Improve process and/or program parameters to avoid them

Update estimated times with real production data

➔ Better costing

➔ Improve production planning

#cnc #program #simulation #optimization