Inspection Planning

MPDV Mikrolab GmbH

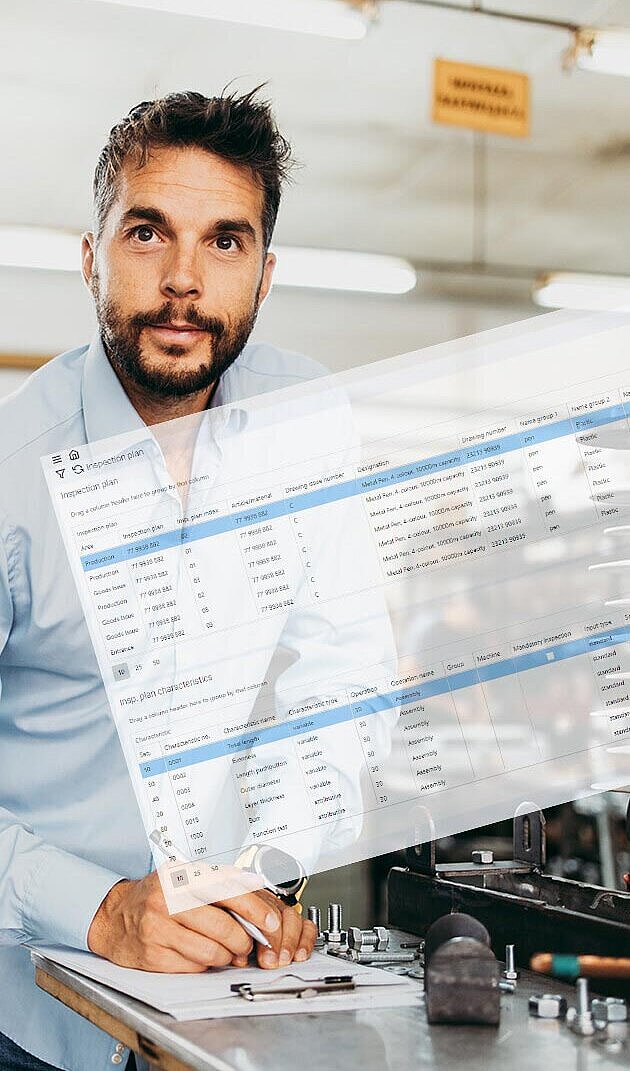

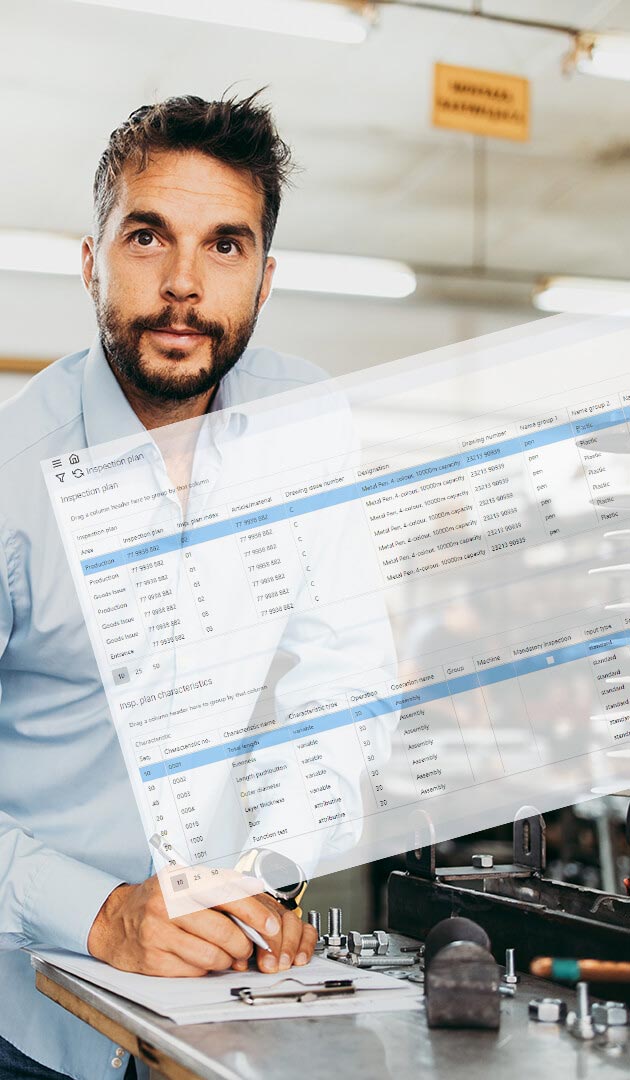

Inspection planning in the Smart Factory

When it comes to quality, good planning is half the battle! Therefore, systematic inspection planning is all the more important. With the mApp Inspection Planning, you can create inspection plans manually or transfer them from higher-level systems such as the ERP (optional). The mApp manages multiple versions of an inspection plan and ensures that only released versions are used to generate inspection tasks.

For each work step you can create different characteristics, specify inspections and assign them to several articles. You specify when a characteristic is inspected and what tolerance is accepted. You also assign the correct test equipment to the inspections. You can store common standards in the system to automatically identify tolerances. The created inspection plans are the basis for different inspection tasks in the Smart Factory.

Optional functions

- Create and manage production control plans according to QS 9000.

- Combine inspections with identical characteristic values into family inspection plans.

- Plan inspections based on cavities (e.g. for multiple molds in plastics processing).

- Plan incoming goods inspection with dynamic inspection severity.

- Transfer inspection characteristics from CAD drawings and FMEA.

Your benefits

You ensure in the planning phase that everything that needs to be inspected is always inspected and specifications and guidelines are adhered to.

Technical information

The mApp Inspection Planning is part of the Quality Management category of HYDRA X.

The mApp stores data in the Virtual Production Reality (ViPR) of MPDV's Manufacturing Integration Platform (MIP).

Inspection Planning in the MIP ecosystem

You can perform and evaluate different inspection tasks based on the managed inspection plans. MPDV also offers the following mApps for this purpose:

- In-Production Inspection: conduct in-production inspections.

- Incoming Goods Inspection: perform incoming goods inspections.

- Quality Analysis & Statistics: evaluate and analyze inspection data.

- FMEA: Failure Mode and Effects Analysis

- Equipment Management: manage tools and test equipment.

#datamanagement #quality #planning #smartfactory #hydra