Hopper - Quality Optimizer

plus10 GmbH

With Hopper, plus10 offers an intelligent software tool for plastics production, which minimizes scrap and cycle time through concrete parameter recommendations and thus allows an increase in good parts by 10 - 17 %.

Injection Molding and AI?

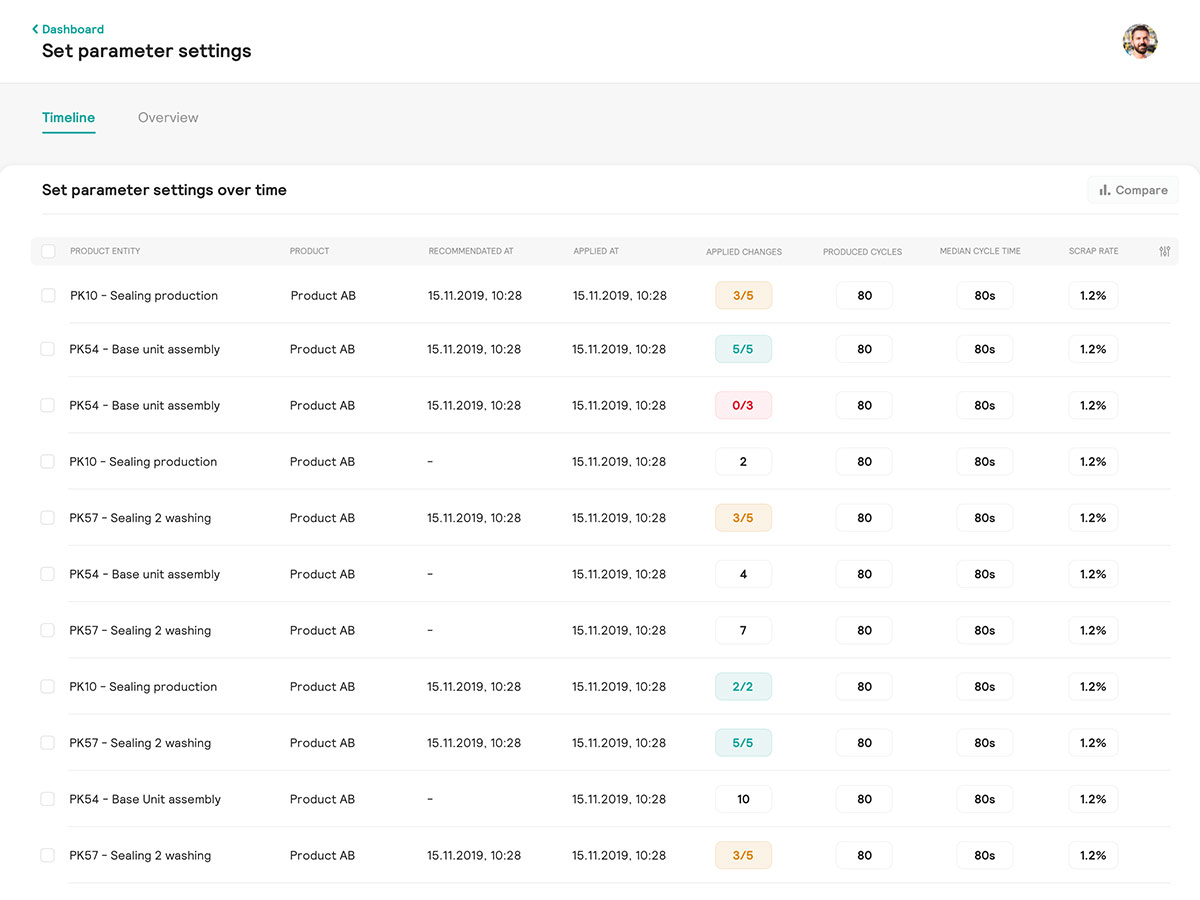

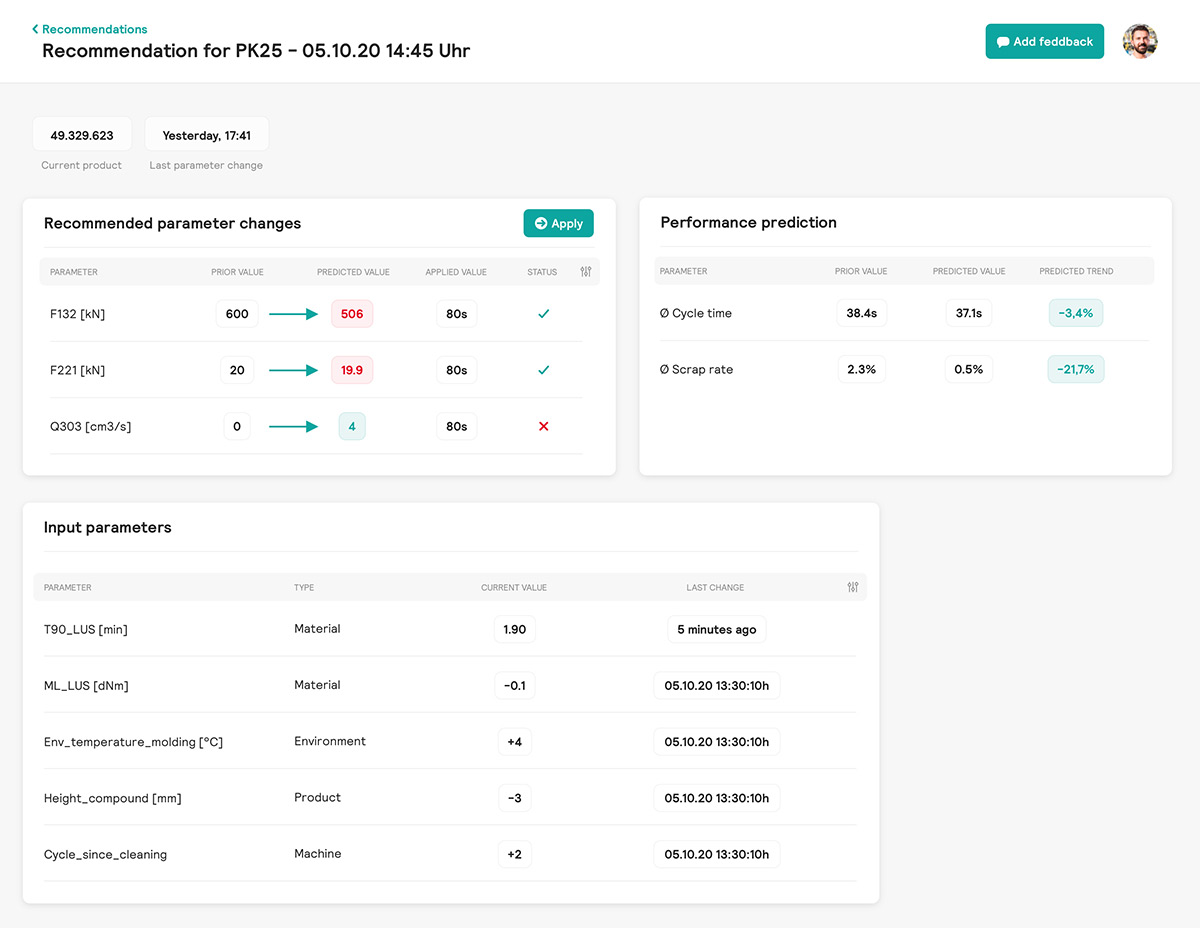

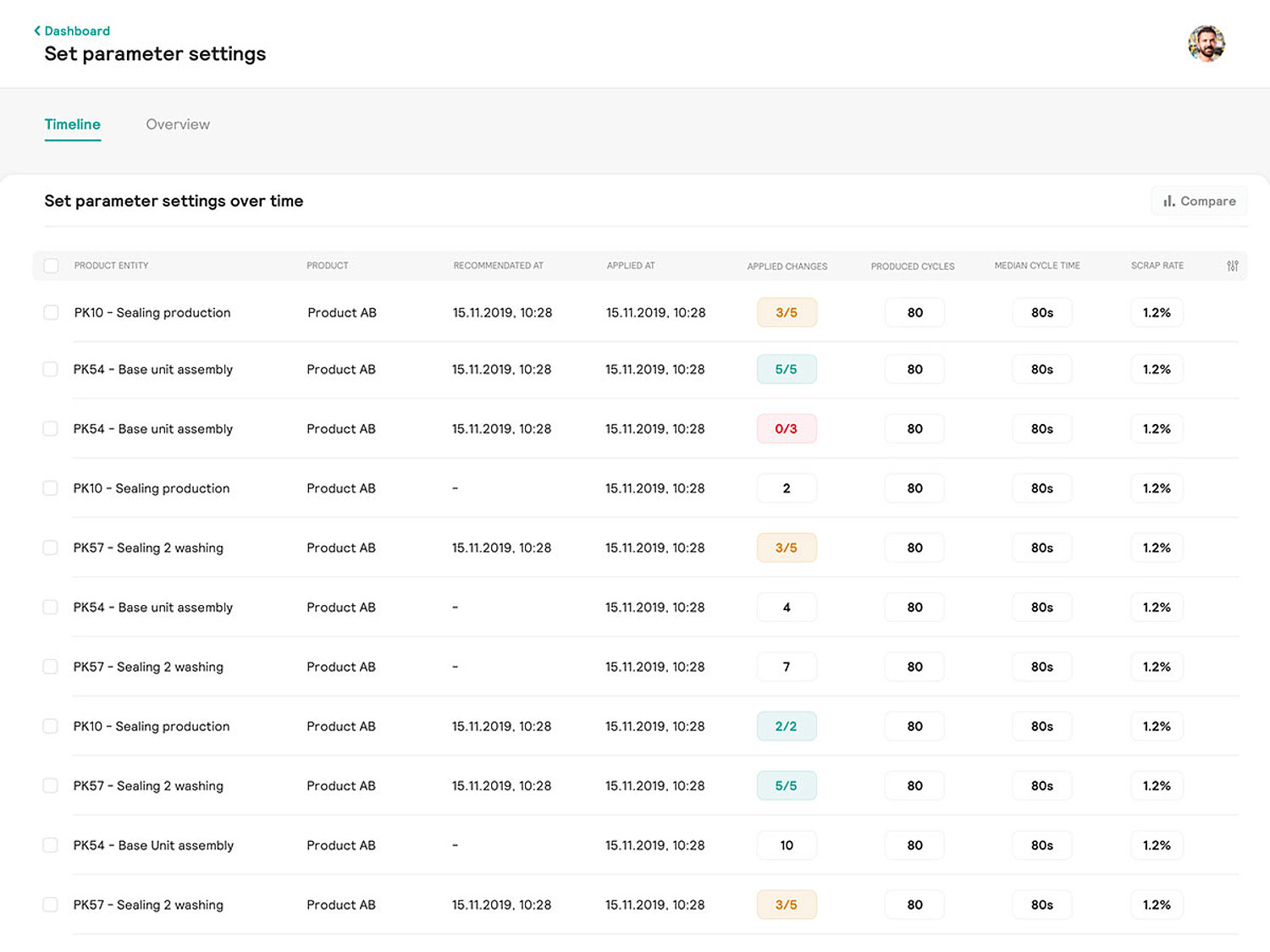

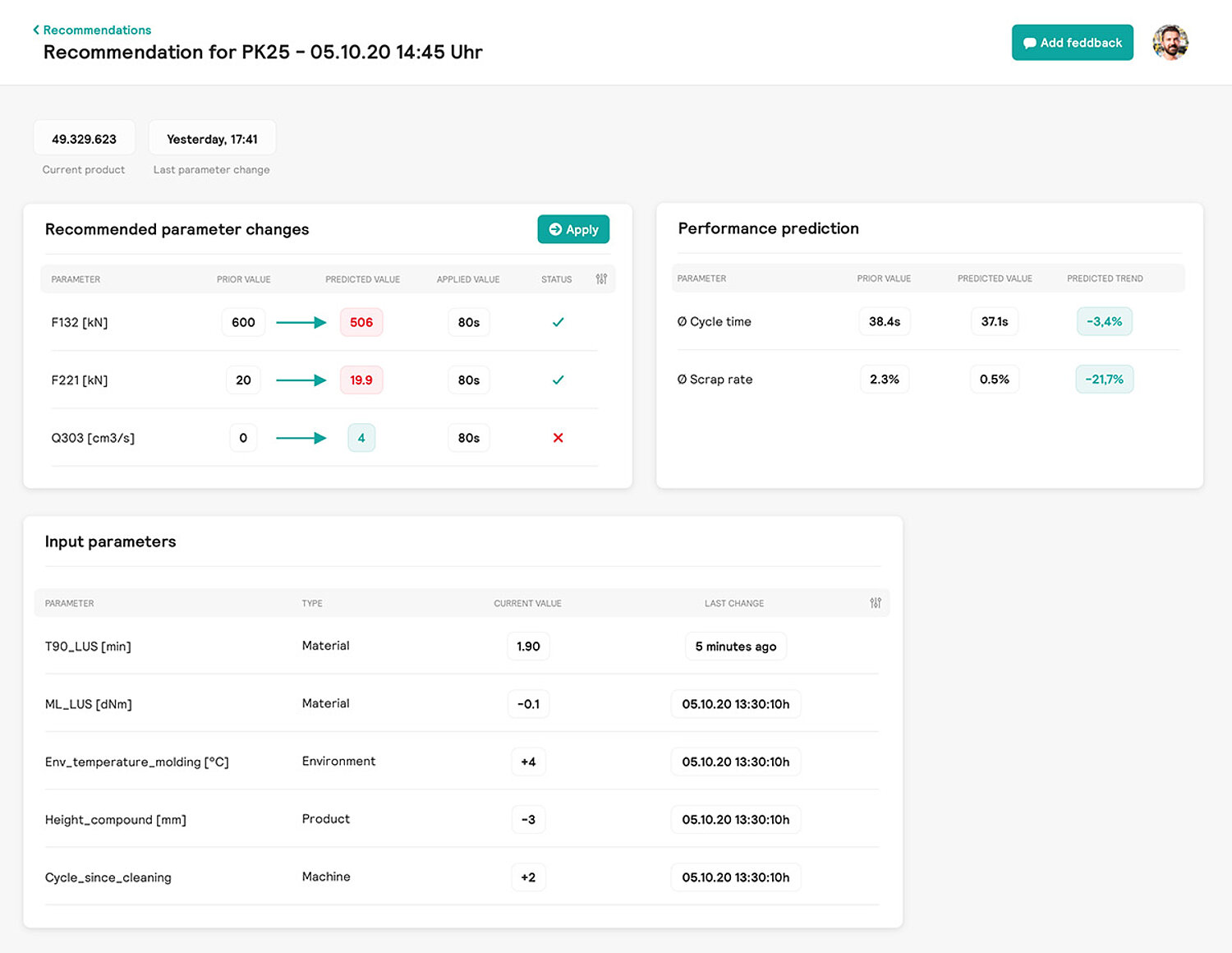

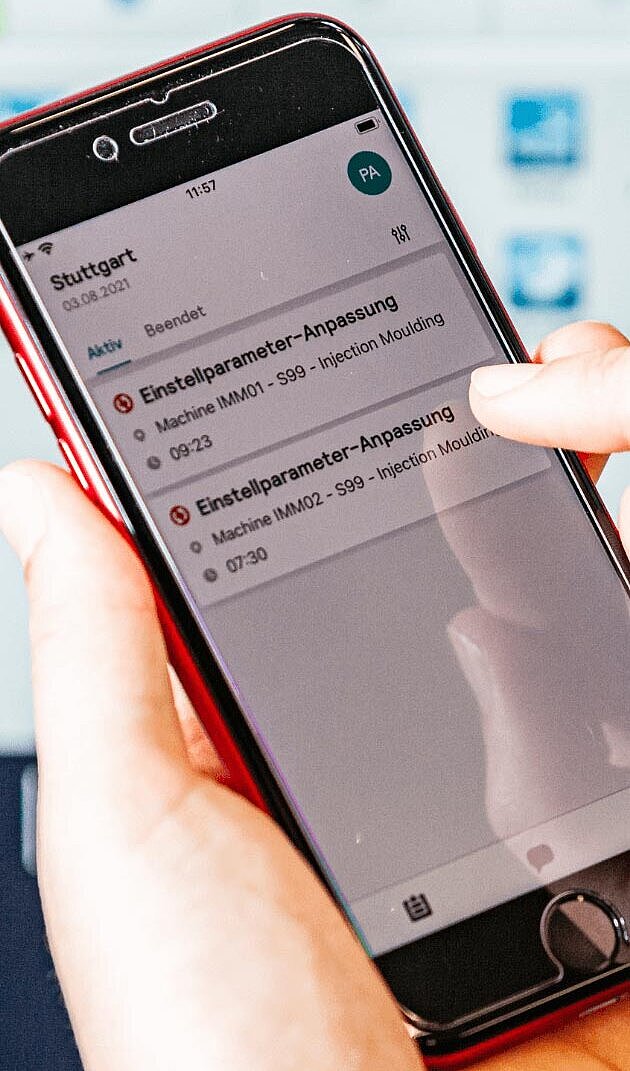

Our parameter optimization tool Hopper automatically generates suggestions, helping you reduce scrap during Setup and production and cycle time in the injection molding process.

Key Benefits:

Reduce Scrap in Injection Molding: Hopper's AI-driven recommendations help you significantly cut down on waste, ensuring a more efficient and cost-effective production process: Shorter Changeover and less in-process scrap!

Continuous Learning AI Models: Our AI models continuously learn the optimal process parameters, allowing the production process to adapt to changing conditions, such as new material batches or slightly changing room climate. These models are transferable to similar machines, making it easy to scale and implement across your operations at one or several factories.

Closed-Loop Optimization: Hopper creates a closed-loop system that automatically adjusts and writes optimized parameters directly to the machine controller, ensuring peak efficiency and quality while eliminating the need for manual adjustments by machine operators.

Customer feedbacks:

- 5-18% Reduction of Rejects:

- to 20% Reduction of Cycle Time

- 10-30% Extension of Multi-Machine Operations

- Click here for an interview with an AI expert about the collaboration with plus10.

- Click here for an overview video of how Hopper works.

- Click here for an interview with a research assistant about the further development of Hopper.

- Click here for an interview video with an expert about Hopper.

#prozessoptimization #machinelearning #optimizationrecommendations #cycletime #scrap