Work Order Controlling

MPDV Mikrolab GmbH

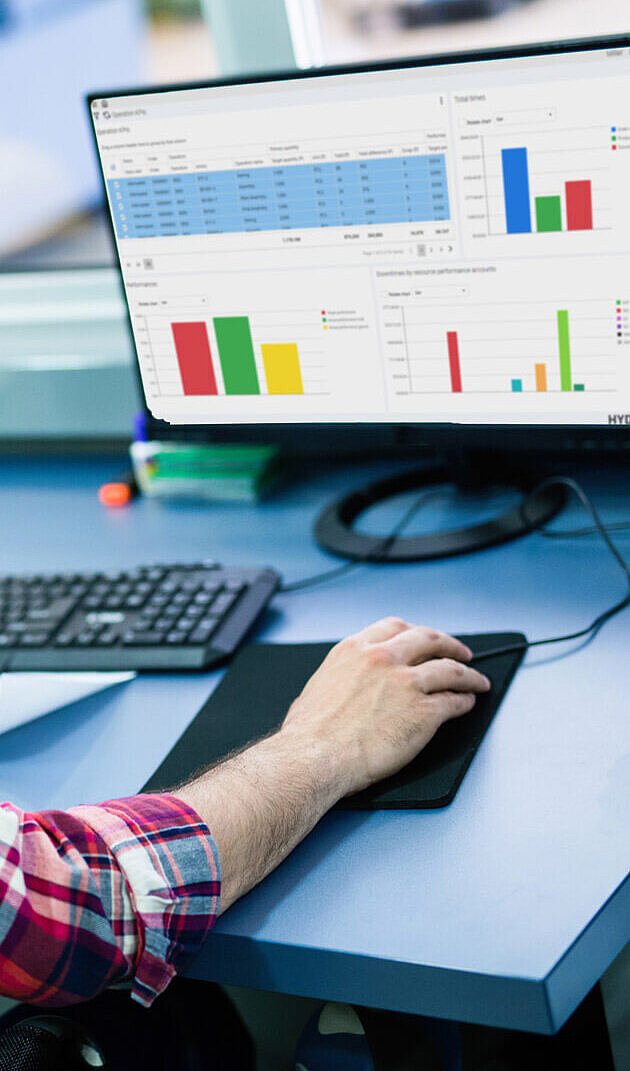

Production KPIs and post calculation

Collected order and operation data are essential, not only for the calculation of production KPIs, but also for post calculations. The mApp Work Order Controlling evaluates the data with regard to deadlines as well as to articles and scrap and thereby permits the analysis and optimization of production.

The mApp shows quantities (e.g. yield, scrap, rework) and times (e.g. total duration, processing time, downtimes, idle times) as actual data and compares the data with the targets for running and completed orders and operations. If scrap is recorded, it can be evaluated with regard to quality and quantity. The software also visualizes schedule deviations and breaks down times and quantities per workplace. Evaluations can be made graphically and in tabular form. Flexible pivot displays are also available for many cases.

Optional functions

- Evaluate order data based on specific persons

- Calculate lean KPIs

- Compare target values like setup times or cycle times with actual data

Your benefits

You provide more efficiency and productivity in your production by evaluating order data. KPIs are absolutely reliable and form a resilient decision-making basis for your course of action.

Work Order Controlling promotes sustainability

A controlling of order data is a good basis for optimizing production and promotes sustainability. Lean processes help uncover and reduce unnecessary waste.

Technical information

The mApp Work Order Controlling is part of the Order Management category of HYDRA X.

The mApp uses data of the Virtual Production Reality (ViPR) of MPDV's Manufacturing Integration Platform (MIP).

Work Order Controlling in the MIP ecosystem

The mApp uses the results of the order data collection application as a basis for the calculation of production KPIs and other evaluations. MPDV also offers the following mApps for this purpose:

- Work Order Management: manage production orders

- Work Order Execution: collect order data in the shop floor

#analytics #dsfm #processoptimization #smartfactory #hydra