Tracking & Tracing

MPDV Mikrolab GmbH

Traceability

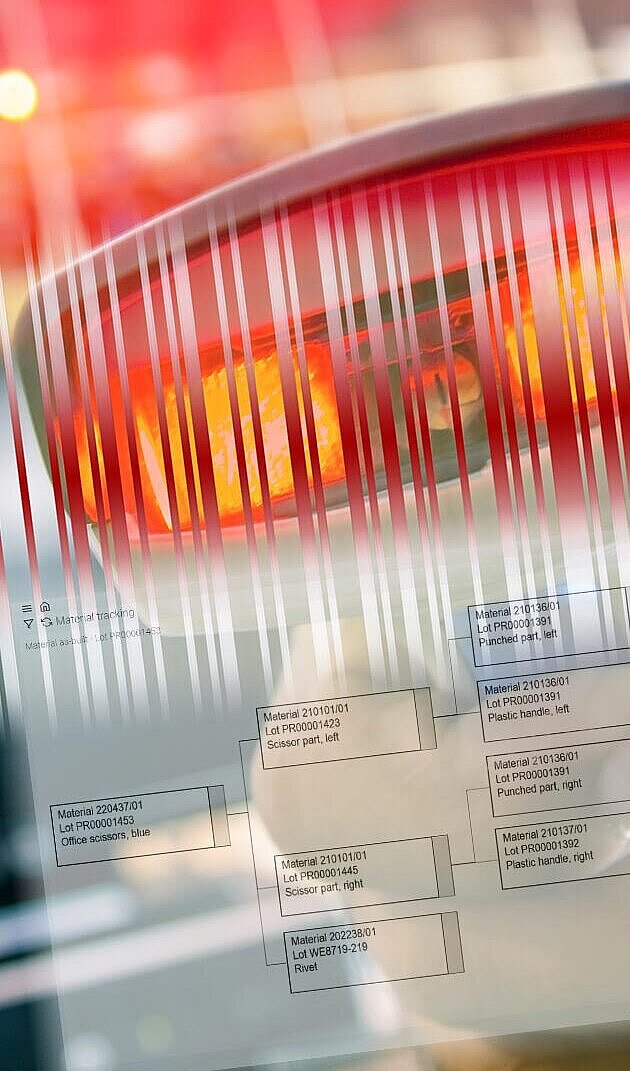

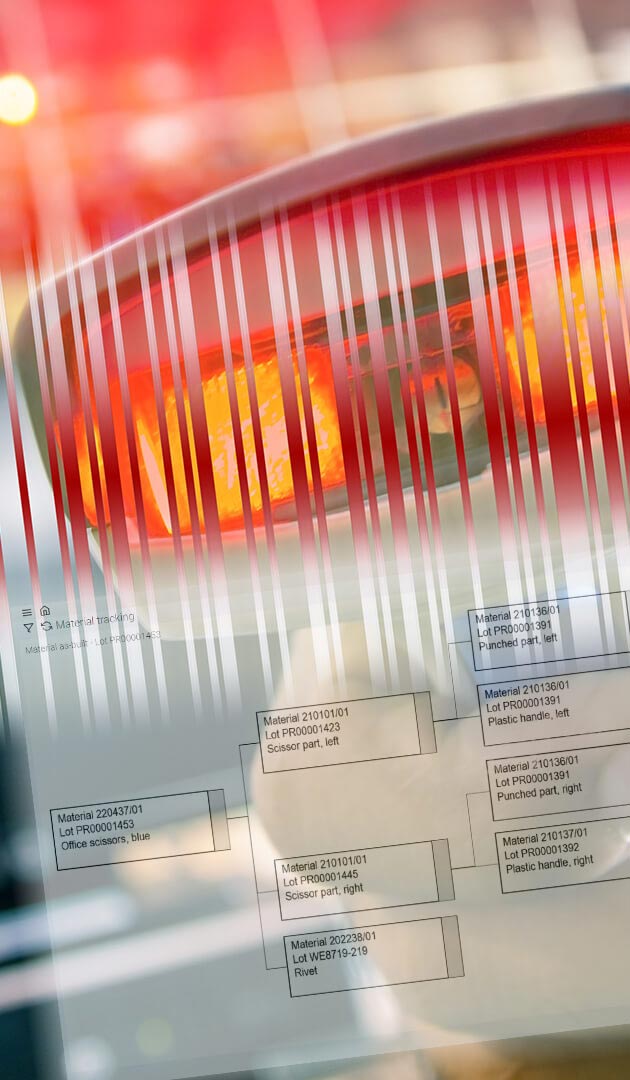

Documentation of the manufacturing process is required in many regulated industries. Part of this involves the accurate recording of materials. The mApp Tracking & Tracing provides both collection functions and applications to evaluate material data. For example, all events relating to a specific material (e.g. logon, change of status or split of a batch) can be recorded and displayed as a history.

By clearly recording lot and batch data when the order is logged on, you can track exactly which material is processed and in which end product. A tree-like evaluation makes it possible to see exactly the materials used to manufacture a product. If there is a deviation in product quality, this application allows you to pinpoint other products that may be affected by the potential defect. Recalls can be reduced to a minimum.

Optional functions

- Record and document individual parts with a serial number.

Your benefits

Use Tracking & Tracing to ensure traceability of your products and thereby fulfill regulatory requirements. You can also better isolate possible recalls and save time and costs.

Technical information

The mApp Tracking & Tracing is part of the Material Management category of HYDRA X.

The mApp uses and stores data in the Virtual Production Reality (ViPR) of MPDV's Manufacturing Integration Platform (MIP).

Tracking & Tracing in the MIP ecosystem

As part of the Smart Factory, the mApp ensures that material usage is accurately documented. MPDV also offers the following mApps for this purpose:

- Work Order Execution: collect order data in the shop floor

- Material & Inventory Management: manage material flow and stocks

- Intralogistics & Packaging: internal transport and packaging processes

#processoptimization #tracing #tracking #trackingandtracing #hydra