Predictive Material Planning

MPDV Mikrolab GmbH

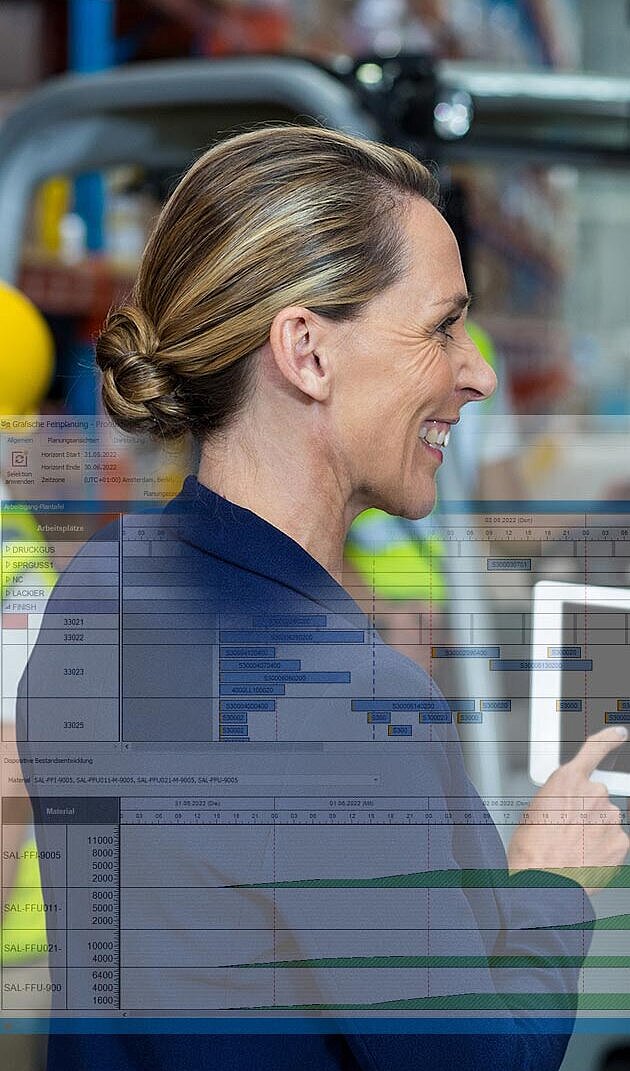

Material Requirements Planning for Your Production

Ensure that the material you need to manufacture is available in sufficient quantities by integrating inventory and WIP levels into your production planning.

The mApp Predictive Material Planning displays required materials in direct relation to orders and operations. According to the orders scheduled, the mApp uses the current stock levels and planned quantities produced and consumed to show material requirements and check material availability. You can also check material availability when scheduling orders.

Your benefits of material requirements planning

Reduce interruptions caused by lack of materials and keep your production running smoothly because you know when a material is required. You can also improve the planning of your logistics processes.

Technical information

The mApp Predictive Material Planning is part of the category Advanced Resource Planning of APS FEDRA.

The mApp uses data of the Virtual Production Reality (ViPR) of MPDV's Manufacturing Integration Platform (MIP).

Predictive Material Planning in the MIP ecosystem

Along with material requirements planning, you can also plan other resources for your production. MPDV provides the following mApps for this purpose:

- Detailed Scheduling: Simple planning of production orders

- Workforce Planning: Flexible planning of workforce requirements

- Secondary Resource Planning: Integrate tools and production resources in the planning

- Energy Demand Planning: Energy-optimized production planning

#productionplanning #scheduling #optimization #material #logistics #fedra