MES for the metal industry

The processing of metal and sheet metal involves a wide range of manufacturing processes, versatile machines, and a broad spectrum of end products. The sheer variety of metals with different properties makes this industry very complex. The industry also suffers from extreme competition, which makes the use of innovative manufacturing IT indispensable.

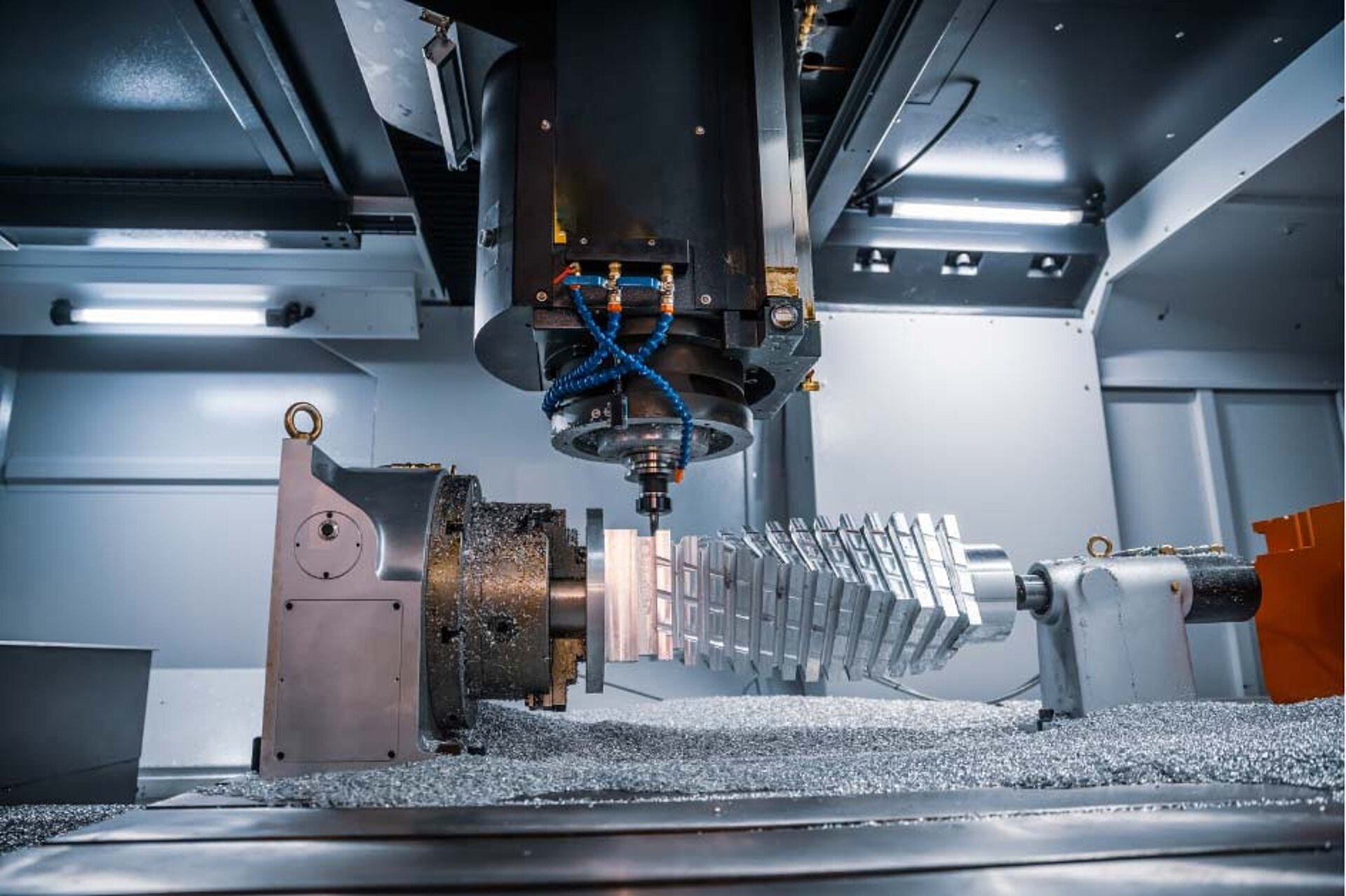

The Manufacturing Execution System (MES) HYDRA X covers the requirements of the metalworking industry in its entirety and also meets requirements that go far beyond the needs of other sectors. HYDRA X, with all its many facets, can be equated with an MES industry solution for metal and sheet metal processing. HYDRA X is based on the tried-and-tested MES tasks of VDI guideline 5600 and offers optimum support for handling complex processes in the metal industry. Included are all typical manufacturing processes such as welding, milling, punching, turning, forging, bending, and CNC machining. Functions for roller maintenance and machining centers are among the selected highlights for metal processing.

Special production technologies, deep value chains, and multi-stage production processes in particular create requirements that are met by combining MES HYDRA X and the Advanced Planning and Scheduling System (APS) FEDRA.

The processing of metal or sheet metal places its specific demands on...

- The processing methods for metal and sheet metal are diverse. Alongside classic machining processes such as bending, drilling, cutting, and joining, MES HYDRA X also masters casting and surface treatment. The Order Management in HYDRA X can deal with all these processes. All kinds of machines and equipment can be connected and configured in the Resource Management.

- Especially during the melting, casting, or heat treatment of metals, large amounts of process data (e.g. temperatures) is collected with HYDRA and then analyzed by correlating data from other production areas.

- Machining centers as well as simple NC machines require programs to process clamped workpieces according to specifications. HYDRA X automatically transfers NC programs to the machine control system.

- Due to high raw material prices, work in progress is a key issue, particularly in metal processing. HYDRA X manages and monitors material in production (WiP) and helps to keep working stock levels low.

MES success stories in metal processing

The following companies rely on MPDV's manufacturing IT: