MES for electronics production

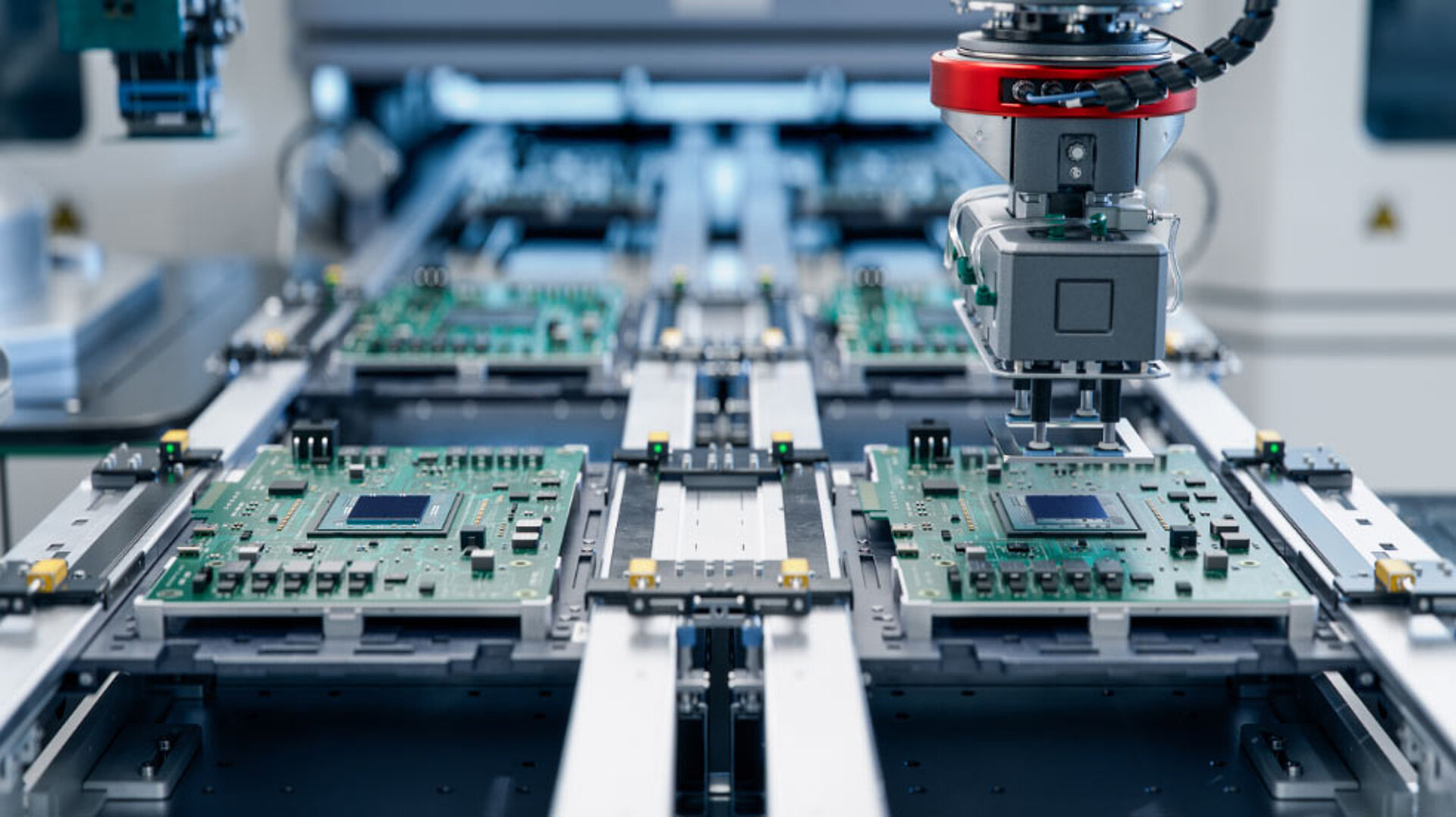

The Manufacturing Execution System (MES) HYDRA X is also at home in the production of electronics. HYDRA X, as any industry solution, fully covers the extensive requirements of electronics production, which exceed the needs of other industries. HYDRA X can integrate all typical process steps of the electronic production.

- Preparation and PCB assembly

- Soldering processes (THT & SMD)

- Testing the assembled circuit boards

- Rework

- Assembly

- Packaging

The focus here is on efficient production as well as the quality of the end products. HYDRA X is suitable for in-house production and for electronic manufacturing services (EMS).

A highlight is the direct connection of all common pick-and-place machines, for example from SIPLACE, Panasonic, Fuji, Universal, or Mydata, which guarantees complete documentation and traceability down to component level. Production planning plays a central role in electronic production. The Advanced Planning and Scheduling System (APS) FEDRA can be fully integrated and has many advantages.

Electronics production and its specific demands on...

- Electronic components are usually sensitive to moisture or have a limited time during which they can be processed. HYDRA X monitors these special material properties and ensures that only those components are processed that are within the permissible parameters.

- The identification of components and component groups plays a central role in production. HYDRA X works with serial numbers on panel and PCB board level and can print labels and tags. HYDRA X therefore provides traceability at all times.

- PCB assembly generates large amounts of data that HYDRA X can process. Here, we deal with standard machine and process data and material data.

- There is a high risk of defects in complex end products, particularly with electronic components during production and at the customer. Using a consistent complaints, rework, and repair management, you can trace defects and repair them. The current location and condition of the affected part or product is known at all times. HYDRA X supports complaint management by providing end-to-end access to all relevant production data.

MES success stories in the production of electronics

The following companies rely on MPDV's manufacturing IT: